Posts tagged ‘Profit Driven’

How to Improve Employee Satisfaction and Retention AND Reduce Labor Costs

Human capital in particular is a critical part of a plant’s success, and needs to be nurtured through leadership, training and other education programs. Ineffective monitoring and mentoring of employees through the lean process negatively impacts the entire process and product quality in particular. The employer has to constantly create enthusiasm with all employees and always pat them on the back for their contribution, no matter how small or how large. Lean always works when the proper leadership strategy is used to implement it. As manufacturers use their new cost efficiencies to wring more output from fewer ![]() employees, care must be taken to select the correct labor reduction.

employees, care must be taken to select the correct labor reduction.

This became a severe issue at one company where the increasing rate of returns due to production quality issues was negatively impacting sales growth. The return rate of product measured in credit dollars was 6% of net sales. The Best-in-Class industry average was 3%. Due to the recent sales revenue decreases, management decided to offset the decreasing sales by reducing the labor force. Unfortunately, the first trims included most of the QA/QC personnel because they were considered to be not directly involved in the daily production throughput of product and thought of as a cost center. Upon joining the company, one of my first assignments was to address the quality issues. By building and leading a cross-functional team which developed, implemented and maintained a successful quality control program based on newly established employee and supplier performance metrics, the team resolved the poor product quality issues. Sales increased 12% in less than 1 year without any increase in labor headcount. Our efforts also resulted in the unanticipated recognition of the flagship facility, by the corporate executive committee, as Quality Factory of the Year for two consecutive years. The program was recognized by the corporate office as a Best Practice and rolled out to the licensee facilities; and I was awarded the Manufacturing Manager of the Year.

issue at one company where the increasing rate of returns due to production quality issues was negatively impacting sales growth. The return rate of product measured in credit dollars was 6% of net sales. The Best-in-Class industry average was 3%. Due to the recent sales revenue decreases, management decided to offset the decreasing sales by reducing the labor force. Unfortunately, the first trims included most of the QA/QC personnel because they were considered to be not directly involved in the daily production throughput of product and thought of as a cost center. Upon joining the company, one of my first assignments was to address the quality issues. By building and leading a cross-functional team which developed, implemented and maintained a successful quality control program based on newly established employee and supplier performance metrics, the team resolved the poor product quality issues. Sales increased 12% in less than 1 year without any increase in labor headcount. Our efforts also resulted in the unanticipated recognition of the flagship facility, by the corporate executive committee, as Quality Factory of the Year for two consecutive years. The program was recognized by the corporate office as a Best Practice and rolled out to the licensee facilities; and I was awarded the Manufacturing Manager of the Year.

Do You Need an Operational Strategy for Remaining Competitive as a US Manufacturer? Embrace LEAN Manufacturing

Firms that fail to fully exploit the strategic power of operations will hamper their competitive abilities and be vulnerable to attack from those competitors who do take advantage of their operations strategy. To exploit the power of operations effectively, operations must be involved throughout the whole of the corporate strategy. Corporate executives sometimes assume that strategy is only for marketing initiatives. Erroneously, they assume that operations have the flexibility to respond positively to changing demands. These assumptions place unrealistic demands upon the operations function. In the run up to the global economic downturn of 2008 and 2009, to a large extent, manufacturers had given up on improvement initiatives such as Lean. Initiatives were still prevalent but core principles had not been adhered to. A “build it and we can sell it” attitude had been adopted with a narrow focus on pure output maximization. Executive management was focused on decreasing headcount and supporting corporate sustainability issues. In years past the focus around head count was all on an aging workforce and preserving tribal knowledge in more automated work flows.

Firms that fail to fully exploit the strategic power of operations will hamper their competitive abilities and be vulnerable to attack from those competitors who do take advantage of their operations strategy. To exploit the power of operations effectively, operations must be involved throughout the whole of the corporate strategy. Corporate executives sometimes assume that strategy is only for marketing initiatives. Erroneously, they assume that operations have the flexibility to respond positively to changing demands. These assumptions place unrealistic demands upon the operations function. In the run up to the global economic downturn of 2008 and 2009, to a large extent, manufacturers had given up on improvement initiatives such as Lean. Initiatives were still prevalent but core principles had not been adhered to. A “build it and we can sell it” attitude had been adopted with a narrow focus on pure output maximization. Executive management was focused on decreasing headcount and supporting corporate sustainability issues. In years past the focus around head count was all on an aging workforce and preserving tribal knowledge in more automated work flows.

Since the collapse, manufacturers have responded to business changes with aggressive cuts to inventory and head count. With the recent cuts in employment, today it is all about learning to do more with fewer people by increasing flexibility, cross training, and ensuring safety requirements are not sacrificed. Doing more with less requires leadership and better communication at all levels which results in increased job performance and more accurate information. Analyzing more accurate information gathered with the use of tools such as Key Performance Indicators and Sales & Operations Planning, managers today can examine what has changed and determine how to intelligently ramp up production and inventory, with an eye toward recapturing core Lean principles.

It is important to remember that the adoption of Lean as a manufacturing strategy is the start of a journey, one that can be very profitable. Certain changes will take longer to effect than others. When Lean is implemented and used properly it can become an effective tool to drive continuous improvement. Once integrated into the culture of the business it becomes the standard for daily operations. Decisions revolve around optimizing all activity and keeping waste to a minimum. Companies that do this better than the competition will be the winners regardless of economic conditions.

Question: Could your company gain a competitive advantage by incorporating LEAN initiatives and tools?

How Successful Companies Listen to the Voice of the Customer

Listening to the voice of customers is vital for every organization. Every interaction that the business has with a customer enables a way to build loyalty or lose it. Customers’ voices allow organizations to keep track of the large number of interactions that transpire between customers and their company. This will permit them to learn effective ways of making their customers happy and keep them coming back. Customers who see results using their interactions with businesses will become loyal to the company. This will promote positive experiences that they may share with others through conversations. The faster a reply comes from a company, the more likely that the business will maintain a good relationship featuring its customers.

Listening to the voice of customers is vital for every organization. Every interaction that the business has with a customer enables a way to build loyalty or lose it. Customers’ voices allow organizations to keep track of the large number of interactions that transpire between customers and their company. This will permit them to learn effective ways of making their customers happy and keep them coming back. Customers who see results using their interactions with businesses will become loyal to the company. This will promote positive experiences that they may share with others through conversations. The faster a reply comes from a company, the more likely that the business will maintain a good relationship featuring its customers.

For example, a company was about to lose a $15 million per year major customer who was not happy with the new product line intended to replace a line that sold $3 million per year through the customer. The sales reps met with the buyer and brought the wants and needs information back to the factory to produce new prototypes. After multiple attempts to get acceptable prototypes made and delivered to the customer, only to have them rejected by the buyer, we invited him and his team to our factory where we met as a single product development team. After several days, we developed a unique line of product that we agreed to manufacture as a proprietary product for this customer. We also made a few minor changes to the original product line and the customer agreed to keep it, in addition to the propriety product, on their showroom floor. After selling both product lines for 6 months, our sales to this customer were tracking $22 million for the year, an increase of approximately 46%.

Question: Is your company missing revenue opportunities not listening the Voice of the Customer?

Management and Leadership in a Newly Created Position

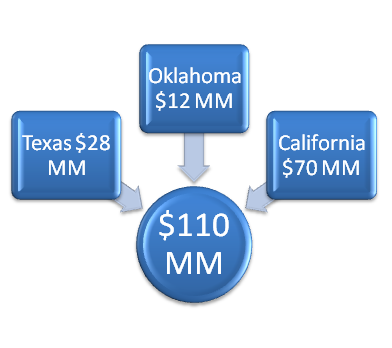

The company was restructuring the management team and reshaping the geographic sales regions of the Corporation. Promoted into the newly created position as Director of Operations – West Region, I was in charge of, with full P&L management responsibilities, the profitability of the company’s largest region comprised of 3 facilities in 3 states having a combined operating budget exceeding $100MM. One of the 3 facilities was underperforming, and needed direction to achieve budgeted EBITDA.

At the end of the fiscal year, all three factories had achieved an EBITDA of 13%, which was higher than planned, setting a new company benchmark and establishing a new trend among all licensee factories.

To achieve this dramatic turn-around, I built and led a cross-functional team that developed, implemented and sustained a successful quality improvement and control program. It should be pointed out that there was no increase in employee headcount; new employees were added through attrition and labor costs remained consistent at 7% of Net Sales. The team’s efforts also resulted in, and laid the groundwork for, unanticipated recognition by Corporate as “The Factory of the Year” for consecutive years 2004 and 2005, from among 7 competing licensee facilities. The program was also recognized as a Best Practice and rolled out to and implemented by all licensee facilities.

How to Increase Production Efficiencies and Throughput by 500% Without Adding Building Square Footage

The CEO and the President of the company had been working with a Big Box retailer for several years to work out a mattress sales program that was expected to increase annual sales revenue to $60 million. Anticipating an agreement within a few months and as the sales unit projections became clearer, it became obvious to management that there was a need to increase production throughput capacities within the same 80K square foot building, with minimal increase in manufacturing labor costs. As the Manufacturing Specialist, I was directed by the CEO to manage the project and lead a team to develop a production layout.

The CEO and the President of the company had been working with a Big Box retailer for several years to work out a mattress sales program that was expected to increase annual sales revenue to $60 million. Anticipating an agreement within a few months and as the sales unit projections became clearer, it became obvious to management that there was a need to increase production throughput capacities within the same 80K square foot building, with minimal increase in manufacturing labor costs. As the Manufacturing Specialist, I was directed by the CEO to manage the project and lead a team to develop a production layout.

The multi-million expansion plan was completed on paper, and presented to the investment group, within five months of our initial discussion in March 2010. Production throughput increased by 500%, from 150 units to 750 units/shift, or 2,250 units/day.

Using Lean Six Sigma initiatives, tools and skills, along with my extensive and diverse manufacturing experience, the expansion was designed to be implemented in thirds, each capable of 250 units per shift. The ROI for the expansion was calculated to be two years or less. The new layout would not only serve the anticipated needs of the Big Box program, but allow for future expansion as well.

Upon completion of the expansion, total production capacity was 2250 per day (over three 8-hour shifts). The details included negotiating the purchase and floor placement of state of the art material movement and processing equipment, and all associated collateral. Efficiencies in labor were gained by acquiring and utilizing the most modern automated equipment available, thereby keeping labor costs at the original levels. The industry also recognized that upon completion, this facility was the most efficient mattress factory in the world.

How to reduce material costs with a high performing supply chain.

Supply chain management factors heavily into lean manufacturing and a tight partnership with suppliers is necessary. The key to lean procurement is visibility. Lean suppliers are able to respond to changes. Suppliers must be able to “see” into their customer’s operations and customers must be able to “see” into their supplier’s operations. This is achieved with the implementation of a two-way flow of information, helping both customer and supplier fix and/or avoid problems and share savings.

For example, the  supply chains among several manufacturing facilities within the same geographic region were

supply chains among several manufacturing facilities within the same geographic region were each operating independently of one another. Although all facilities had basically the same vendors, the laid-in costs were markedly different. These raw material cost differences manifested themselves most noticeably during the monthly P&L COGS analysis. Each supplier was brought into the loop of our lean activities. Through these discussions it very quickly became obvious that the supplier in many cases was not aware of how their product was used. Plant tours were arranged between the suppliers and the factories. Purchasing agents met with customer service personnel, thereby matching a face with a name. Our IT staff met with their IT staff to set up e-procurement and automated procurement. E-procurement processes transactions such as strategic sourcing, bidding, and reverses actions using web-based applications. Automated procurement uses software that removes the human element from multiple procurement functions and integrates with financials. Trucking companies were brought into the equation, and as a trio, were able to negotiate long term, money saving contracts for the delivery of materials. As the person responsible for the P&L, I was able to develop a culture of continuous improvement. Through negotiation, coordination, consolidation, and systematizing the Supply Chain between facilities and suppliers, we were able to negotiate savings of $100K in material and realized a reduction of $75K in labor costs within the first year.

each operating independently of one another. Although all facilities had basically the same vendors, the laid-in costs were markedly different. These raw material cost differences manifested themselves most noticeably during the monthly P&L COGS analysis. Each supplier was brought into the loop of our lean activities. Through these discussions it very quickly became obvious that the supplier in many cases was not aware of how their product was used. Plant tours were arranged between the suppliers and the factories. Purchasing agents met with customer service personnel, thereby matching a face with a name. Our IT staff met with their IT staff to set up e-procurement and automated procurement. E-procurement processes transactions such as strategic sourcing, bidding, and reverses actions using web-based applications. Automated procurement uses software that removes the human element from multiple procurement functions and integrates with financials. Trucking companies were brought into the equation, and as a trio, were able to negotiate long term, money saving contracts for the delivery of materials. As the person responsible for the P&L, I was able to develop a culture of continuous improvement. Through negotiation, coordination, consolidation, and systematizing the Supply Chain between facilities and suppliers, we were able to negotiate savings of $100K in material and realized a reduction of $75K in labor costs within the first year.

Question: Are you losing bottom line dollars due to a supply chain not performing at maximum efficiency?

How to Create a Competitive Edge and Reduce Manufacturing Costs by Improving Process Efficiencies.

A primary focus of lean manufacturing is to eliminate process inefficiencies; that is, eliminate anything that does not add value to the final product. In this respect, excessive lead times are an inefficiency that carries with it a high cost, one of which is excess inventory. Excessive lead time not only reduces the ROI on manpower, raw material and finished inventories, but it is a major obstacle in the pursuit of customer satisfaction and revenue growth.

A company was looking for a competitive edge to generate sales revenue which was declining due to the recent economic downturn. As a leading supplier to the home furnishings industry, product pricing and quality were already as competitive as possible. The only part of the sales closure trio to improve upon was service by reducing the lead time between order receipt and shipment. The company needed to implement a strategy to reduce these lead times and allow the manufacturer to be more responsive to customer demands. By developing and executing manufacturing flow and process improvements, I led the team, using Lean Six Sigma tools and initiatives, as we reduced lead times on built to order products up to 50%, from 12 weeks to 6 weeks. With the implementation of these strategies and in response to this competitive edge, sales increased. As the shorter lead times were sustained, the company quickly established a reputation for having the quickest order turn time in the industry.

A company was looking for a competitive edge to generate sales revenue which was declining due to the recent economic downturn. As a leading supplier to the home furnishings industry, product pricing and quality were already as competitive as possible. The only part of the sales closure trio to improve upon was service by reducing the lead time between order receipt and shipment. The company needed to implement a strategy to reduce these lead times and allow the manufacturer to be more responsive to customer demands. By developing and executing manufacturing flow and process improvements, I led the team, using Lean Six Sigma tools and initiatives, as we reduced lead times on built to order products up to 50%, from 12 weeks to 6 weeks. With the implementation of these strategies and in response to this competitive edge, sales increased. As the shorter lead times were sustained, the company quickly established a reputation for having the quickest order turn time in the industry.

Question: Are you experiencing customer dis-satisfaction and unacceptable revenue growth due to lengthy and excessive order fulfillment lead times?

How to remain competitive as a manufacturer in the USA.

In order to survive today, companies must respond to the cost pressures of globalization by producing more economically and more efficiently than ever. Domestic bedding manufacturers can survive only if they take the right steps to refine their processes and sharpen their business focus. That is the view held by most manufacturing experts. It is said that today’s factory has to focus on what it does best. Products need to be made resourcefully and need to be differentiated from that of the competition. This must include the development of products and processes with the customer experience in mind. Eliminate waste, create efficiency…these four words describe the foundation of efficient operations. Some waste exists in every system. From manufacturing and assembly, to supply chain and customer service, some waste is hidden within all processes. The need for an operations strategy that reflects and supports the corporate strategy is crucial for the success of the company. Many US manufacturing operations have included as part of their strategy Lean Six Sigma initiatives which are the most widely recognized approach to defining, measuring, analyzing, improving and controlling processes and product costs to drive out waste and improve and sustain efficiency. Product costs are controlled by three elements: material, labor and overhead.

Although, in most cases, material costs make up by far the largest portion of costs, followed by labor and overhead, each has a strong influence on the other. For example, a company can have the lowest material costs in the country by way of the best performing supply chain, but if the product is manufactured using inefficient processes, or no process is in place to monitor and control labor, cost can creep above that of the competition. The positive connection between the five elements can be explained in the captioned principles.

Although, in most cases, material costs make up by far the largest portion of costs, followed by labor and overhead, each has a strong influence on the other. For example, a company can have the lowest material costs in the country by way of the best performing supply chain, but if the product is manufactured using inefficient processes, or no process is in place to monitor and control labor, cost can creep above that of the competition. The positive connection between the five elements can be explained in the captioned principles.

Over the next several weeks, I’ll be expanding on the strategies for remaining competitive as a manufacturer in the United States.